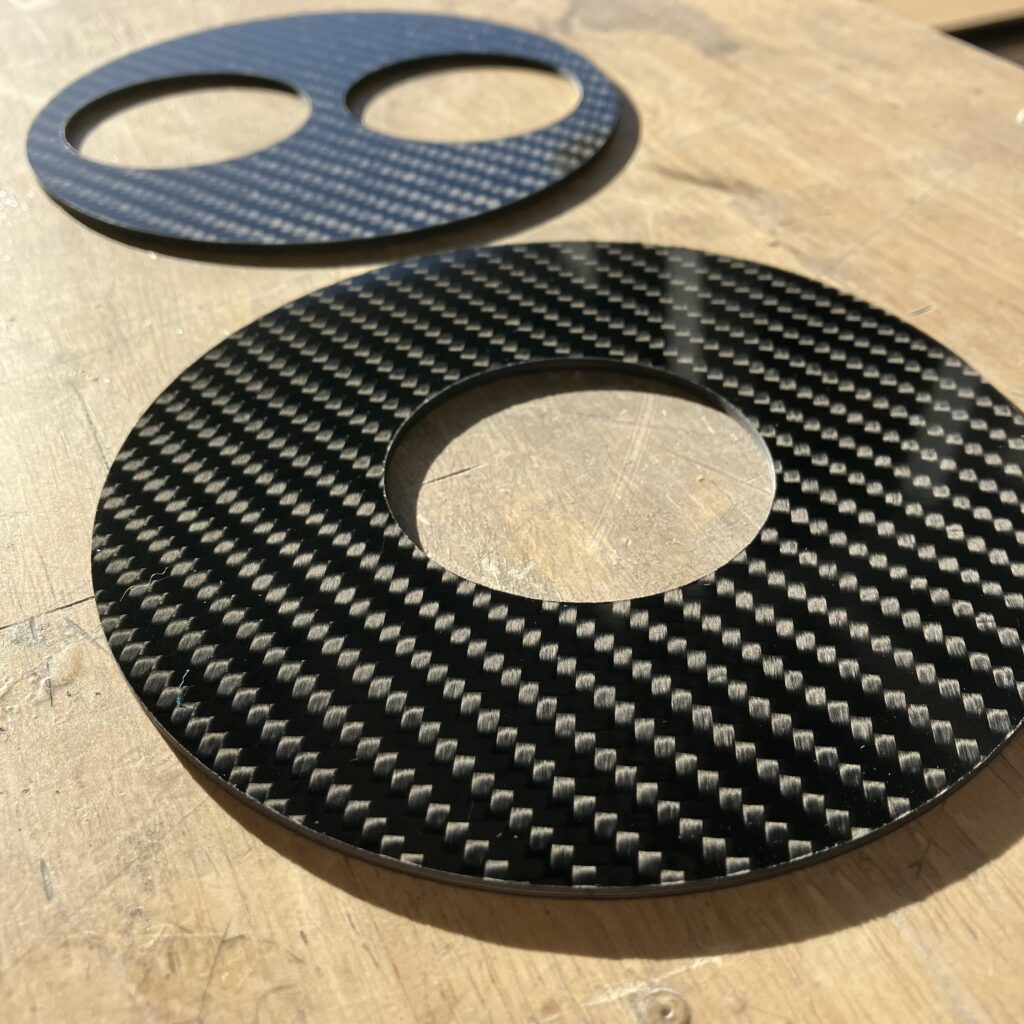

Carbon fibre has revolutionized industries ranging from aerospace to automotive, thanks to its exceptional strength-to-weight ratio and rigidity. And when it comes to shaping this incredible material, CNC (Computer Numerical Control) cutting takes center stage, bringing precision and efficiency to the production process.

How does CNC cutting work?

CNC cutting is a subtractive manufacturing process where a computer-controlled machine precisely removes material from a workpiece. Carbon fibre plates, known for their layered structure, require intricate cuts and shapes, and CNC machines are up to the task.