Carbon Fibre Repairs: Restoring Strength and Resilience

Carbon fibre has revolutionized industries with its remarkable strength, lightweight properties, and versatility. From aerospace to automotive, sports equipment to marine vessels, carbon fibre composites have become a preferred material for their exceptional performance. However, like any other material, carbon fibre can sustain damage over time or due to accidents. Thankfully, carbon fibre repairs offer a practical and effective solution to restore the structural integrity and extend the lifespan of these high-performance materials.

Understanding Carbon Fibre:

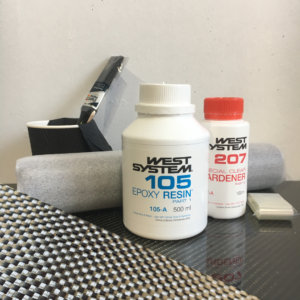

Before delving into the intricacies of carbon fibre repairs, let’s briefly understand what makes this material so exceptional. Carbon fibre consists of thin strands of carbon, which are tightly woven together to form a durable, high-strength fabric. The carbon fibres are combined with a matrix material, typically epoxy resin, which provides support and protects the fibres. This combination results in a composite material that exhibits remarkable strength-to-weight ratio, stiffness, and resistance to corrosion.

Common Types of Damage:

Despite its exceptional properties, carbon fibre can experience damage in various ways, such as impact, abrasion, fatigue, or manufacturing defects. Some common types of damage include:

-

Delamination: Delamination occurs when the layers of carbon fibre separate from each other, weakening the structure.

-

Surface Damage: Scratches, chips, or gouges on the surface can compromise the integrity of the carbon fibre, potentially leading to further damage.

-

Impact Damage: High-velocity impacts can cause visible cracks, fractures, or even punctures in the carbon fibre structure.

-

Fatigue Damage: Repeated stress cycles over time can lead to fatigue damage, resulting in micro-cracks that can propagate and compromise the structural integrity.

Interested in carbon fibre repair services? Contact us today to get a quote.

Carbon Fibre Repair Techniques:

Repairing damaged carbon fibre requires a meticulous approach to ensure the restored part retains its original strength and performance. Several repair techniques are commonly employed:

-

Patching: For minor surface damage or localized cracks, patching with carbon fibre fabric and epoxy resin is a common repair method. The damaged area is carefully sanded, cleaned, and then layered with a patch, which is saturated with epoxy resin. This process helps restore the strength and aesthetics of the damaged part.

-

Layup Repair: In cases of larger damaged areas or delamination, a layup repair technique is employed. This involves removing the damaged section, preparing the surface, and then layering multiple plies of carbon fibre fabric with epoxy resin to rebuild the structure.

-

Filament Winding: Filament winding is a specialized repair technique used for cylindrical carbon fibre structures, such as bike frames or pressure vessels. It involves wrapping continuous carbon fiber filaments under tension around the damaged area and impregnating them with resin, creating a strong and seamless repair.

-

Composite Bonding: In cases of severe damage or complex structures, composite bonding techniques are employed. This involves bonding pre-fabricated carbon fibre patches or reinforcing elements using structural adhesives, ensuring a strong and durable repair.